I have been fascinated with the idea of 3D printing for years. It started with a fascination with the 3D printed jewelry from Nervous System, a pair of artists who use simulations to auto-generate unique designs based on biology. I was also quite taken by recent news of a 3D printed cast for broken bones, based on a patient's own x-rays and 3D scans. Then I stumbled upon Hot Pop Factory, a local company that combined both 3D printing and scanning into a single workshop. By partnering with Draft Print 3D, participants were also given the chance to print a small 3D object to bring home. I rounded up a few friends and we registered for the next one.

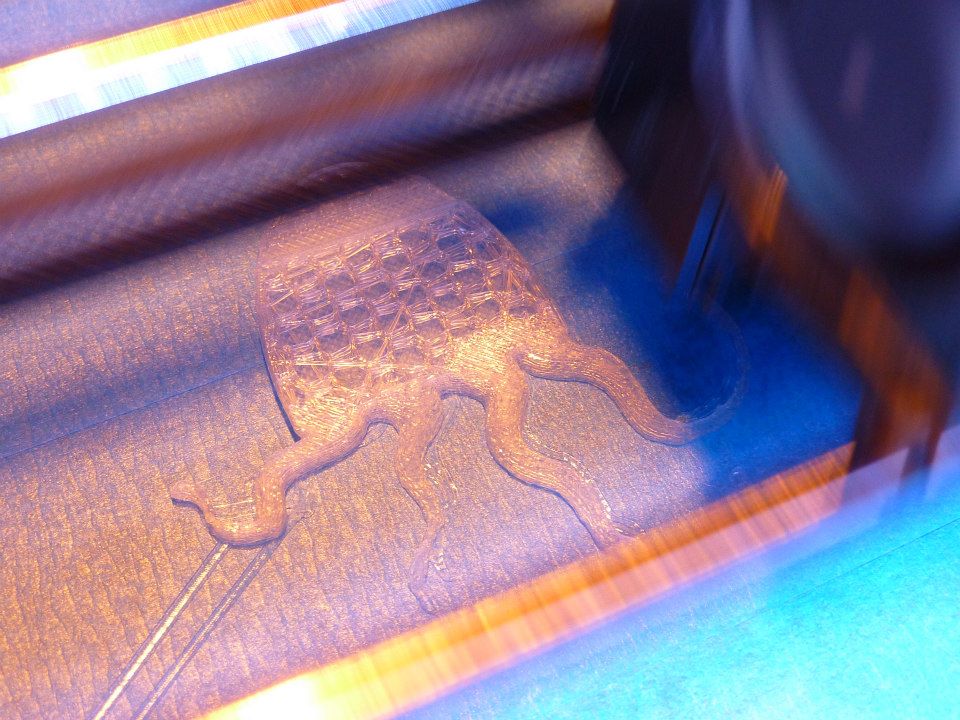

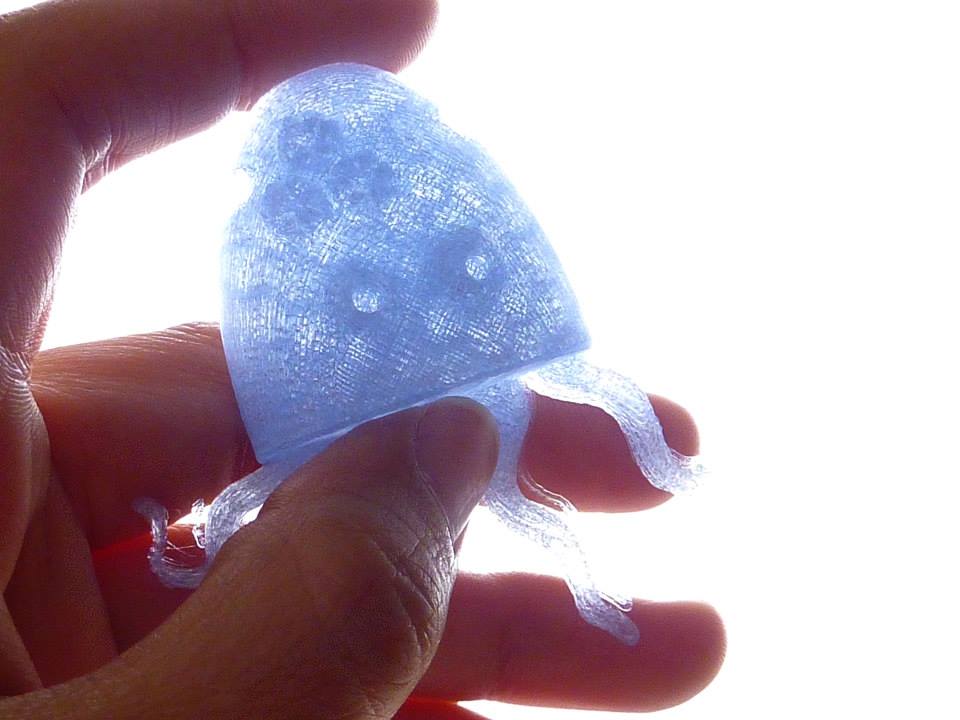

Using pre-made templates and a few simple tools in MeshMixer, a free program made by Autodesk, we had a lot of fun putting shapes together and exploring the interface. We learned about the constraints of simple designs for 3D printing, and got to watch our pieces grow from the bottom up.

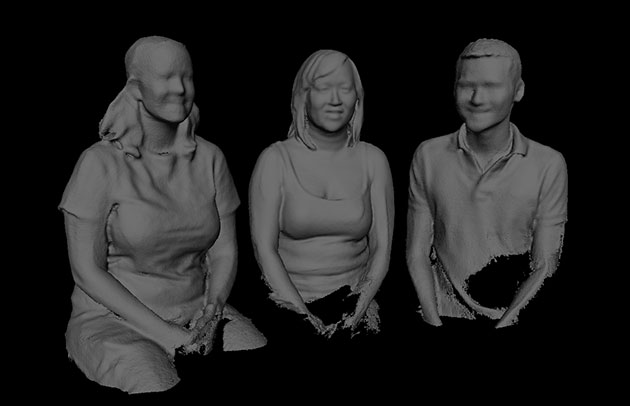

As an extra bonus, we each got a 3D scan using an Xbox Kinect camera and ReconstructMe freeware. I think mine turned out the best! You can even see my eyes. TIP: rotate *slowly* during the scan.